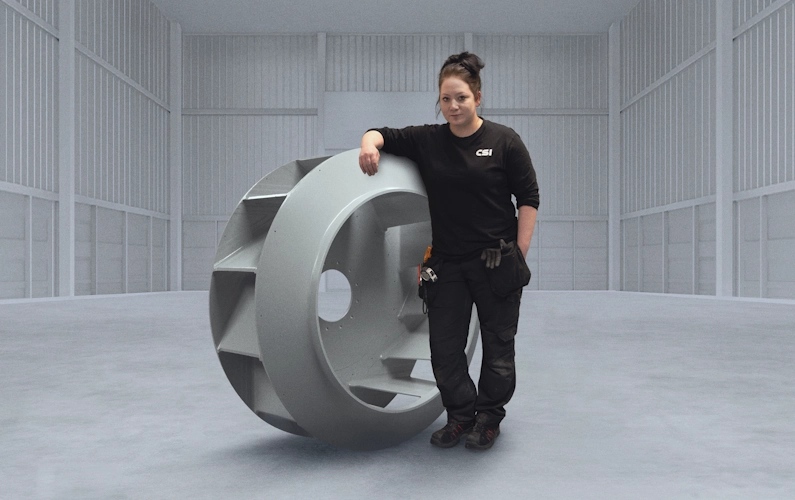

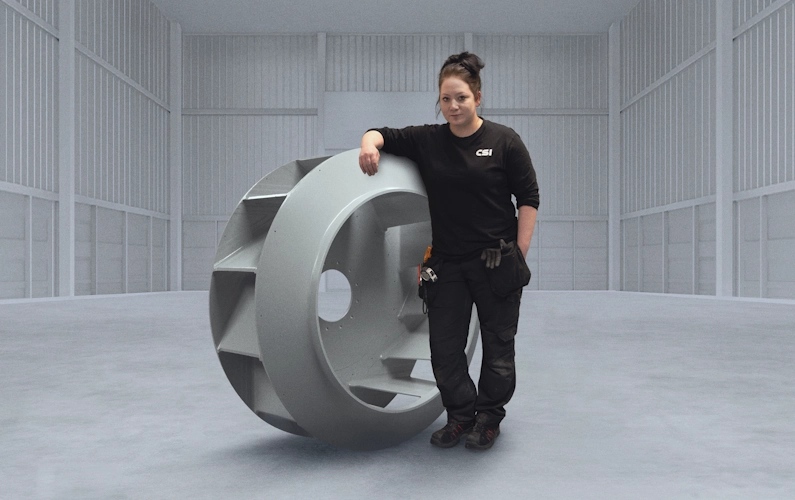

CSI Composite Solutions and Innovations Ltd has over the last decade put a lot effort to develop next generation impeller with Xtended performance, Xtended sustainability and safety and with Xtended freedom of design.

Several hundred units are already installed and running in industrial processes in numerous locations. Our experienced team provides you with patent pending solutions not comparable to any other at the market. Contact us to learn more!

Benefits

Xtended performance

- Xtended performance – We typically achieve a 50-70% weight reduction compared to steel impellers, resulting significantly improved operating efficiency and remarkably low structural stress levels.

- Xtended coverage of applications – we provide competitive solutions for both OEM and retrofit applications

- Xtended annual operating hours – reduced downtime and maintenance hours, as frequent inspections are unnecessary compared to welded or cast solutions

Xtended sustainability and safety

- Xtended lifespan – typically 3-5 times longer than that of steel and even longer when compared to cast aluminium impellers. All impellers undergo NDT inspection prior to shipping to ensure top quality.

- Xtended sustainability – Optimal ramp-up and ramp-down control, along with spinning speeds tailored to process requirements, combined with extended lifespan, deliver exceptional sustainability.

- Xtended chemical resistance to acid gases, even surpassing that of acid-resistant steel, is a standard feature of composite impellers

- Xtended safety – if a foreign object enters the air tunnel, Xtend Impellers’ breakaway mode minimizes damage, offering a safer alternative compared to steel impellers

Xtended freedom of design

- Xtended potential of shape and dimensions – composite materials offer design flexibility in both shape and size. Currently, we manufacture impellers ranging from 500 mm to over 2500 mm, tailored to specific designs and dimensions

- Xtended service level – our patent-pending process ensures short lead times through highly efficient engineering and manufacturing. All we need from you are the main dimensions, RPM-level and operation conditions and we will take care of the engineering. Additionally, we offer inspection and maintenance services to ensure reliable product performance throughout its entire lifecycle.

Contact us!